Ningbo Dicheng Machinery Co.,ltd

Address:Room 1202.NO.1107,Tiantong North Road Zhonghe Street Yinzhou District Ningbo

City Zhejiang Province China

The contact: Lucy(General Manager)

Phone: 13968328508

Tel: 0574-87267001

Fax: 0574-87267002

E-mail: wll@nbchengdi.com

Website: www.nbdicheng.com

This paper introduces the axial parts deep hole drilling. In the process of drilling, rational utilization of bakelite supporting set, increase the drill pipe rigidity, and before the tool front end increase the guidance, improve the inner hole and cylindrical coaxial degree and the quality of the surface roughness, improving the quality of processing, the processing of high speed rotating hollow shaft parts inner hole is of great significance.

Has been a long time, the deep hole processing machinery processing difficulties. In my company, is the key to the nc boring machine boring axis hollow parts, its hole and cylindrical alignment, straightness and surface roughness quality tolerance requirements are relatively high, size tolerance are strict. Over the years, the hollow of the boring axis always restricts the deep hole processing complete sets of production.

Here in my company CNC floor-type boring boring axis (HFBC1636) as an example. The material is 38 crmoala, boring axis conditioning 265 ~ 285 HBW. This part of the hole length to diameter ratio is about 92:1, the conventional deep hole drilling methods, it is difficult to ensure design requirements. To this end, we to the deep hole drilling process for the following improvement, as shown in figure 1.

According to my company's existing equipment, we choose TK2125A when drilling deep hole drilling machine tool, cutting tool used with ejector drilling deep hole processing, in order to push the boring way processing.

Drilling process is: the car hole to hole drilling and phi 38 mm, outside circle (eliminate hole and cylindrical coaxial) to eliminate stress, straightening and lateral, expanding, boring, grinding, expanding, boring depth to 3566 mm to 74 + 0. Phi, depth to the pattern size and subsequent working procedure.

Previously, when drilling, end by machine tool self-centering chuck clamping workpiece, on the other side on top pressure plate, with a center frame auxiliary support.

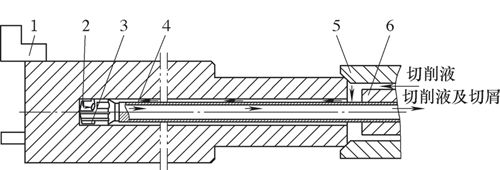

Drilling, the workpiece is rotating, drill pipe rotation and axial feed in the opposite direction. Started drilling, rely on a guide hole, drill bit around 25 ~ 40 mm long article supporting, workpiece right end has a set of supporting pipe. Cutting fluid from right side into the workpiece hole, the chip is entered into the pipe inner hole bit front-end chip mouth eduction.

Due to the drilling using push boring processing, drill bit and drill pipe under axial pressure, but only a bit and drill rod end bearing, central pipe without bearing, cause in the process of drilling, drill pipe insufficient rigidity, prone to bend, meet hard point is easy to produce the deflection and vibration in processing of inner hole and cylindrical alignment, straightness and roundness is very poor, inner hole surface roughness is bad, also easy to cause waste. The concrete is shown in figure 2.

Figure 2

In order to improve the quality of hollow shaft boring processing, we have done the following methods of drilling technology improvement:

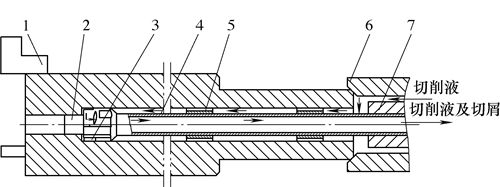

(1) drilling, the drill pipe installed on the support sleeve, a 300 mm, to effectively support rod. But must have enough when the deep hole drilling cutting fluid into the workpiece hole, the cutting tool for cooling, and will be processed for the drill pipe inner hole away (see figure 3). To this end, we will support sleeve cylindrical design into rectangle spline shape, made of bakelite can not only effectively supporting rod, increase the drill pipe rigidity, reduce the wear and tear of between drill pipe and bearing sleeve, and can satisfy the cutting fluid smoothly into the workpiece hole, the cutting tool for cooling, to chip away.

(2) according to the principle of heavy drill, reamer bit before adding guiding parts, improve the inner hole cylindrical alignment.

(3) in order to improve the service life of the bakelite supporting set, we will support sleeve early immersion in cutting fluid, reduce the bakelite set of wear and tear. Double spindle machining center

As shown in figure 3.

Figure 3

After the above improvements, we in the large hollow floor type boring machine processing deep hole boring axis, whether the shape tolerance, or size, surface roughness, can fully meet the design requirements.